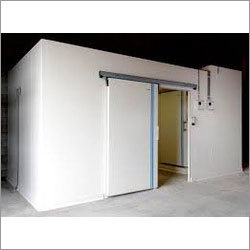

Storage Cold Room

Price 250000 MXN ($)/ Unit

Storage Cold Room Specification

- Product Type

- Storage Cold Room

- Usage

- Food Preservation, Pharmaceuticals, Industrial Storage

- Power

- 2 kW - 15 kW (Depending on Capacity)

- Cooling System

- Air Cooling / Direct Cooling System

- Refrigerant

- R404a / R134a / R22

- Voltage

- 220V/380V, 50Hz/60Hz

- Defrost Type

- Automatic / Manual Defrost

- Air Volume

- High-Efficiency Internal Circulation Fans

- Function

- Low Temperature Storage and Preservation

- Application

- Vegetables, Fruits, Dairy, Meat, Ice Cream, Medicine Storage

- Door Type

- Hinged Door / Sliding Door (customizable)

- Temperature

- -25C to +18C (adjustable as required)

- Thickness(mm)

- 60mm / 80mm / 100mm / 120mm (PUF Panel)

- Installation

- On-Site Modular Assembly

- Internal Lighting

- LED Light Fittings

- Compressor Brand

- Emerson / Bitzer / Tecumseh / Equivalent

- Panel Material

- Pre-painted Galvanised Sheet (PPGI) Both Sides

- Control System

- Digital Microprocessor Controller

- Floor Material

- Anti-Slip Aluminium / Stainless Steel

- Insulation Density

- 40-42 kg/m³ (PUF)

- Humidity Control

- Optional (On Request)

- Capacity

- 500 cu ft to 10000 cu ft (customizable)

Storage Cold Room Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 15 Units Per Day

- Delivery Time

- 25 Days

- Packaging Details

- Transport

- Main Domestic Market

- All India

About Storage Cold Room

We are your one stop frozen item solution shop; we bring to our clients with top grade quality of Storage Cold Room preferably semi-perishable and non-perishable items. Our cold room is highly suitable for agriculture sector, horticulture, floriculture units etc. This keeps a controlled atmosphere within the unit so as to maximize the shelf life of the stored products/ items. Special attention is given for the manner in which various foods are stored so that they depend on the quantities in which they are brought and the type and size of the storage space. Each part of the Storage Cold Room is consisted of walls, ceiling, floor, doors and corners and special panels designed for the purpose to ensure perfect fit.

Other Details:

- Prevent rooting of food items

- Increase the shelf life of frozen items

- Optimal power consumption

Superior Panel Construction

Built with pre-painted galvanised sheets (PPGI) on both sides and premium polyurethane foam insulation, the cold room guarantees long-lasting performance and exceptional thermal efficiency. This robust panel material minimizes energy loss and maintains optimal storage conditions, safeguarding sensitive items within a secure, cost-effective environment.

Flexible Capacity and Customization

Available in sizes from 500 cu ft to 10,000 cu ft, these cold rooms can be customized to meet your unique storage requirements. Options for door type, panel thickness, and internal layout provide unmatched adaptability, making implementation effortless for various business scales and storage applications.

Advanced Climate Control Technology

Employing digital microprocessor controllers and high-performance compressors (Emerson, Bitzer, Tecumseh, or equivalent), precise temperature regulation is assured from -25C up to +18C. Optional humidity control and efficient air-circulation fans optimize product preservation, reducing spoilage risks while enabling automatic or manual defrost cycles.

FAQs of Storage Cold Room:

Q: How is the cold room installed at my site?

A: Our cold rooms are designed for on-site modular assembly. Experienced technicians deliver and assemble the unit at your desired location, ensuring minimal disruption and rapid deployment. Modular panels with integrated insulation allow for efficient, reliable installation, tailored to your facilitys space and requirements.Q: What materials are used for panel and flooring construction?

A: The panels are constructed from pre-painted galvanised sheet (PPGI) on both sides, with polyurethane foam insulation (40-42 kg/m) between layers. The flooring options include anti-slip aluminium or stainless steel, both providing durability and safety for staff during operation and maintenance.Q: When should I request humidity control, and how does it work?

A: Humidity control is optional and may be requested if you need to store items sensitive to moisture, such as certain pharmaceuticals, fruits, and vegetables. When added, it regulates moisture levels within the room using integrated sensors and controllers, protecting against dehydration or excess humidity.Q: Where can these cold rooms be used, and for what applications?

A: Our cold rooms are versatile and suitable for food preservation, pharmaceuticals, and industrial storage. Typical applications include storage of vegetables, fruits, dairy, meat, ice cream, and medicines. They can be installed in warehouses, food processing units, pharmaceutical plants, and distribution centers across India.Q: What is the benefit of using a digital microprocessor controller in the cold room?

A: A digital microprocessor controller offers precise temperature control, easy monitoring, and automated functions such as defrosting. This ensures stable environments for sensitive products, reduces energy waste, and simplifies management, providing peace of mind for operators and owners alike.Q: How do I select the appropriate temperature and panel thickness for my needs?

A: Temperature settings can be adjusted from -25C to +18C according to your specific storage requirements. Panel thickness options (60mm, 80mm, 100mm, and 120mm) are chosen based on desired insulation performance; thicker panels offer enhanced thermal efficiency for lower temperatures or longer storage durations.Q: What is the process for ordering and customization?

A: Begin by contacting us with your capacity, application, and specific requirements (such as door type, humidity control, flooring, and panel thickness). We guide you through design selection, provide an estimate, and schedule on-site installation. Our team ensures customized solutions for optimal storage and energy efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Room Category

Modular Cold Room

Price 258000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Air Cooled

Application : Industrial, Commercial, HORECA

Voltage : 220240V/50Hz or 380415V/50Hz

Temperature : 20C to +10C adjustable

Commercial Cold Room

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Air Cooled / Water Cooled

Application : Supermarkets, Pharma, Restaurants, Hotels, Food Processing

Voltage : 220V/380V, 50Hz

Temperature : 18C to +5C (adjustable)

Walk In Freezer Room

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Aircooled

Application : Food, Pharmaceuticals, Chemicals

Voltage : 220V/380V

Temperature : 18C to 25C

Prefabricated Cold Room

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Air Cooled / Water Cooled

Application : Hotels, Restaurants, Warehouses, Laboratories

Voltage : 220V/380V, 50Hz

Temperature : 5C to 25C (adjustable)

Send Inquiry

Send Inquiry