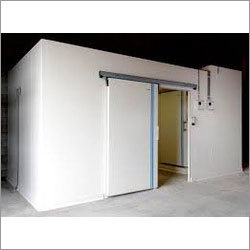

Customized Cold Room

Price 258000.0 INR/ Unit

Customized Cold Room Specification

- Product Type

- Customized Cold Room

- Usage

- Food Storage, Pharmaceuticals, Industrial Application

- Cooling System

- Remote / Monoblock

- Application

- Commercial & Industrial

- Door Type

- Sliding / Hinged Door

- Refrigerant

- R404a / R22

- Power

- Depends on cold room size and configuration

- Thickness(mm)

- 60mm / 100mm / 120mm

- Function

- Cooling, Preservation, Freezing

- Air Volume

- Customizable (based on room size)

- Voltage

- 220V / 380V

- Defrost Type

- Electric / Hot Gas

- Temperature

- -25C to +18C adjustable

- Lighting

- LED energy saving lamp

- Floor Type

- Anti-slip Embossed Aluminum

- Noise Level

- Low Noise Operation (<55dB)

- Installation

- On-site assembly and commissioning

- Panel Surface

- Color coated Steel / Stainless Steel

- Capacity Range

- From 5 m up to 500 m

- Insulation Material

- High-density Polyurethane (PU) Foam

- Humidity Control

- Optional

- Access

- Emergency exit included

- Compressor Brand

- Copeland / Bitzer / Emerson

- Control System

- Digital temperature controller

Customized Cold Room Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Day

- Delivery Time

- 25 Days

- Packaging Details

- Transport

- Main Export Market(s)

- [, ]

- Main Domestic Market

- , [, ', A, l, l, I, n, d, i, a, ', ]

About Customized Cold Room

We regularly upgrade our working methodology in order to manufacture and export premium quality Customized Cold Room. This cold room is standard cold room chambers to freeze beverage, food, meat, vegetable, fruit, chemical, pharmaceutical material, etc. The given cold room is extremely suitable for working in high ambient conditions. This cold room is equipped with highly efficient compressors that provide quick chilling. Accessible in different standard heights, lengths and widths, this customized cold room can also be customized as per the specific requirements of patrons.

Specification

|

Temperature Range |

-15 to +15 (Celsius) |

|

Size |

10 x 10 x 8 Feet |

|

Insulation Thickness |

60mm |

|

Usage/Application |

Food Industry |

FAQs of Customized Cold Room:

Q: How is the temperature regulated within the customized cold room?

A: Temperature regulation is managed by a digital temperature controller, allowing users to adjust settings between -25C and +18C, ensuring optimal preservation for diverse storage needs.Q: What materials are used for insulation and panel surfaces?

A: High-density polyurethane (PU) foam serves as the primary insulation material, while the cold room panels come with color-coated steel or stainless steel surfaces, promoting strength and longevity.Q: When is humidity control recommended for cold room operation?

A: Humidity control is optional and is suggested when storing products sensitive to moisture, such as pharmaceuticals or certain food items, to maintain consistent internal conditions and product quality.Q: Where are these cold rooms typically installed?

A: Customized cold rooms are installed on-site across various facilities in India, including commercial kitchens, warehouses, pharmaceutical manufacturing units, and industrial settings.Q: What is the process for on-site assembly and commissioning?

A: The cold room is delivered to the customers location, where skilled technicians assemble the panels, install equipment, configure the control systems, and commission the unit to ensure full operational readiness.Q: How does the cold room benefit commercial and industrial users?

A: It offers reliable temperature and humidity control, low operating noise, energy efficiency, and customizable design options, thereby safeguarding products and optimizing operational efficiency for food, pharmaceutical, and industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Room Category

Modular Cold Room

Price 258000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial, Commercial, HORECA

Cooling System : Air Cooled

Temperature : 20C to +10C adjustable

Voltage : 220240V/50Hz or 380415V/50Hz

Insulation Cold Room

Price 320000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Commercial and Industrial Refrigeration

Cooling System : Air Cooled / Water Cooled

Temperature : 40C to +18C

Voltage : 220V/380V

Storage Cold Room

Price 250000 MXN ($) / Unit

Minimum Order Quantity : 1 Unit

Application : Vegetables, Fruits, Dairy, Meat, Ice Cream, Medicine Storage

Cooling System : Air Cooling / Direct Cooling System

Temperature : 25C to +18C (adjustable as required)

Voltage : 220V/380V, 50Hz/60Hz

Prefabricated Cold Room

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Hotels, Restaurants, Warehouses, Laboratories

Cooling System : Air Cooled / Water Cooled

Temperature : 5C to 25C (adjustable)

Voltage : 220V/380V, 50Hz

Send Inquiry

Send Inquiry