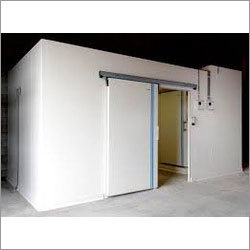

Insulation Cold Room

Price 320000.0 INR/ Unit

Insulation Cold Room Specification

- Temperature

- -40C to +18C

- Door Type

- Hinged or Sliding Door

- Application

- Commercial and Industrial Refrigeration

- Power

- 2.5kW 15kW (depending on room size)

- Refrigerant

- R134a / R404a / R507

- Cooling System

- Air Cooled / Water Cooled

- Air Volume

- 1800 6000 m/h

- Thickness(mm)

- 60mm / 80mm / 100mm / 120mm / 150mm

- Function

- Preserving and storing products at controlled temperatures

- Defrost Type

- Electric / Hot Gas Defrost

- Voltage

- 220V/380V

- Product Type

- Insulation Cold Room

- Usage

- Food Storage, Pharmaceuticals, Hospitality, Industrial

- Service temperature range

- -40°C to +30°C

- Panel Density

- 38-42 kg/m³

- Floor Type

- Anti-slip steel or Aluminium Chequered Plate

- Insulation Material

- Polyurethane Foam (PU) / Polyisocyanurate (PIR)

- Control System

- Digital Microprocessor Based

- Installation

- Modular, Easy to Assemble

- Lighting

- LED Interior Light

- Humidity Control

- Optional

- Panel Material

- Pre-Painted Galvanized Steel / Stainless Steel

- Compressor Brand

- Emerson / Bitzer / Danfoss

- Noise Level

- <65 dB(A)

Insulation Cold Room Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Day

- Delivery Time

- 25 Days

- Packaging Details

- Transport

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Insulation Cold Room

Reliable Temperature Control for Multiple Applications

Achieve consistent cooling performance with advanced digital microprocessor controls and a reliable selection of compressor brands. This modular cold room infrastructure is tailored for precise preservation across food, pharmaceutical, hospitality, and industrial sectors, ensuring sensitive products remain at optimum temperatures during storage.

Durable and Hygienic Construction

The cold room is built with high-quality pre-painted galvanized steel or stainless steel panels and robust insulation material (PU/PIR) for superior thermal stability. Anti-slip flooring enhances safety, while the choice of hinged or sliding doors provides practical access solutions for diverse operational needs.

Energy Efficient and Easy to Assemble

Enjoy lower energy consumption through a choice of air- or water-cooled systems, LED interior lighting, and insulation panels of multiple thicknesses. Its modular design makes the installation process seamless and scalable, reducing downtime and operational disruption.

FAQs of Insulation Cold Room:

Q: How is the cold room installed and assembled?

A: The cold room features a modular, easy-to-assemble design. Panels and accessories arrive pre-fabricated and can be quickly connected and secured on-site, minimizing installation time and simplifying expansion or relocation.Q: What are the benefits of using PU or PIR insulation material in the panels?

A: Polyurethane (PU) and polyisocyanurate (PIR) insulation provide superior thermal efficiency, ensuring minimal heat transfer and stable temperature control. Their high panel density (3842 kg/m) enhances energy savings and longevity of the cold room structure.Q: When should I choose a hinged door versus a sliding door for my cold room?

A: Select hinged doors for spaces where frequent, quick access is needed and sliding doors for applications with space constraints or high-traffic areas, as they require minimal clearance and ease heavy material movement.Q: Where can this insulation cold room be used effectively?

A: This solution serves commercial and industrial settings including food storage facilities, pharmaceutical warehouses, hospitality venues, and other locations requiring controlled-temperature environments to preserve sensitive products.Q: What process does the control system use to maintain temperature?

A: The digital microprocessor-based control system continuously monitors and regulates internal conditions, adjusting compressor, defrost, and humidity settings as needed to maintain set temperatures between 40C and +18C or up to +30C for service.Q: How does humidity control add value to the cold room?

A: Optional humidity control helps prevent product degradation, especially for goods sensitive to moisture, such as pharmaceuticals and fresh produce. It contributes to improved shelf life and product integrity.Q: What advantages does LED interior lighting offer?

A: LED lights provide bright, energy-efficient illumination inside the cold room, improving visibility during operations while maintaining low energy consumption and minimizing temperature fluctuations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Room Category

Modular Cold Room

Price 258000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240V/50Hz or 380415V/50Hz

Cooling System : Air Cooled

Application : Industrial, Commercial, HORECA

Temperature : 20C to +10C adjustable

Commercial Cold Room

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V, 50Hz

Cooling System : Air Cooled / Water Cooled

Application : Supermarkets, Pharma, Restaurants, Hotels, Food Processing

Temperature : 18C to +5C (adjustable)

Customized Cold Room

Price 258000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V / 380V

Cooling System : Remote / Monoblock

Application : Commercial & Industrial

Temperature : 25C to +18C adjustable

Storage Cold Room

Price 250000 MXN ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V, 50Hz/60Hz

Cooling System : Air Cooling / Direct Cooling System

Application : Vegetables, Fruits, Dairy, Meat, Ice Cream, Medicine Storage

Temperature : 25C to +18C (adjustable as required)

Send Inquiry

Send Inquiry