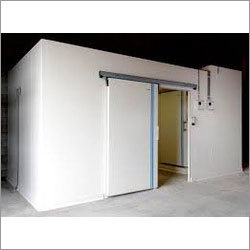

Prefabricated Cold Room

Price 150000 INR/ Unit

Prefabricated Cold Room Specification

- Product Type

- Prefabricated Cold Room

- Cooling System

- Air Cooled / Water Cooled

- Usage

- Food Storage, Pharmaceuticals, Chemicals

- Refrigerant

- R22 / R404A / R134A

- Power

- As per capacity (customized)

- Thickness(mm)

- 60 mm / 80 mm / 100 mm / 120 mm (customizable)

- Temperature

- -5C to -25C (adjustable)

- Air Volume

- 800~4000 m/h (Depending on system)

- Application

- Hotels, Restaurants, Warehouses, Laboratories

- Voltage

- 220V/380V, 50Hz

- Defrost Type

- Automatic Electric Defrost

- Door Type

- Hinged or Sliding Door

- Function

- Chilling/Freezing/Cold Storage

- Shelf Type

- Optional Racks/Shelves

- Compressor Brand

- Emerson / Danfoss / Bitzer (As per requirements)

- Humidity Control

- Optional

- Installation

- Modular, easy assembly and relocation

- Floor Type

- Anti-slip Aluminum / Stainless Steel

- Panel Density

- 40 ± 2 kg/m³ PU Foam

- Dimensions

- Custom sizes available

- Control Panel

- Digital controller with temperature display

- Panel Material

- Pre-painted galvanized steel/SS304/Aluminum sheet

- Insulation

- High-density polyurethane

- Finish Type

- Smooth / Embossed

- Noise Level

- Low Noise Operation

- Lighting

- Internal LED Lighting

- Access Ramp

- Customizable (if required)

- Energy Efficiency

- High, with tight sealing and PU insulation

Prefabricated Cold Room Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Day

- Delivery Time

- 25 Days

- Packaging Details

- Transport

- Main Domestic Market

- All India

About Prefabricated Cold Room

Customizable and Modular Design

The cold rooms are modular, enabling quick assembly, hassle-free relocation, and simple expansion. With customizable thickness, dimensions, doors (hinged or sliding), and access ramps, these units seamlessly fit a wide range of users and facility layouts, including hotels, restaurants, warehouses, and more.

Superior Insulation and Energy Efficiency

Panels are constructed using high-quality materials and insulated with high-density polyurethane foam, ensuring minimal temperature variation and high energy efficiency. The tight sealing mechanism keeps cold air inside, reducing operational costs and enhancing product integrity.

Precision Controls and Optional Features

A digital controller lets users easily monitor and adjust internal temperatures from -5C to -25C, with optional humidity control for specialized storage needs. Internal LED lighting and the possibility to add racks or shelves further enhance usability and visibility.

FAQs of Prefabricated Cold Room:

Q: How can I customize the size and features of the prefabricated cold room for my facility?

A: Our cold rooms are available in custom sizes and thicknesses (60 mm, 80 mm, 100 mm, 120 mm) to suit varying needs. Options such as door type (hinged or sliding), internal shelving, humidity control, and access ramps can also be tailored. Let us know your requirements during the ordering process.Q: What is the process for installing and assembling the cold room on-site?

A: Each unit is modular, allowing for straightforward on-site assembly with minimal disruption. The panels are prefabricated and designed for easy interlocking, meaning setup and relocation can be completed quickly. Our team or certified partners can assist with professional installation if required.Q: Where can these cold rooms be used and what applications do they support?

A: Prefabricated cold rooms are suitable for a wide variety of settings, including hotels, restaurants, warehouses, laboratories, and other commercial spaces. They are ideal for storing food, pharmaceuticals, chemicals, and any products requiring controlled chilling or freezing.Q: What type of panel and floor materials are used, and how do they benefit users?

A: Panels are available in pre-painted galvanized steel, SS304, or aluminum, ensuring durability and corrosion resistance. Floors are made of anti-slip aluminum or stainless steel for enhanced safety and longevity, making them suitable for demanding environments.Q: How does the cold room maintain energy efficiency and low noise operation?

A: High-density polyurethane foam insulation and precision tight sealing minimize temperature fluctuations, reducing energy consumption. Branded compressors (Emerson, Danfoss, or Bitzer) deliver reliable cooling with low noise levels, contributing to a quieter and more economical operation.Q: What are the control and monitoring features included in the cold room system?

A: A digital control panel provides precise temperature management, allowing users to set storage temperatures between -5C and -25C. Optional humidity control, internal LED lighting, and automatic electric defrost further enhance operational convenience.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Room Category

Modular Cold Room

Price 258000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial, Commercial, HORECA

Voltage : 220240V/50Hz or 380415V/50Hz

Temperature : 20C to +10C adjustable

Cooling System : Air Cooled

Storage Cold Room

Price 250000 MXN ($) / Unit

Minimum Order Quantity : 1 Unit

Application : Vegetables, Fruits, Dairy, Meat, Ice Cream, Medicine Storage

Voltage : 220V/380V, 50Hz/60Hz

Temperature : 25C to +18C (adjustable as required)

Cooling System : Air Cooling / Direct Cooling System

Customized Cold Room

Price 258000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Commercial & Industrial

Voltage : 220V / 380V

Temperature : 25C to +18C adjustable

Cooling System : Remote / Monoblock

Cold Storage Room

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Fruit, vegetable, seafood, meat, dairy, pharmaceuticals

Voltage : 220V/380V, 50/60Hz

Temperature : 20C to +10C

Cooling System : Aircooled/Watercooled condenser

Send Inquiry

Send Inquiry